DVS Applications

The origins of Dynamic Vapor Sorption (DVS) can be traced back to pharmaceutical development. Nowadays, DVS has established itself as a standard method in many other industrial sectors such as food and feed, fertilizer and agrochemicals, fine chemicals, detergents, cosmetics, building materials, textiles, archeology or electronics. The versatile proUmid multi-sample sorption systems are used worldwide by leading scientists and manufacturers and are already standard equipment in most laboratories.

Please click below for examplary applications where DVS analysis is a highly valued tool in the design process of new products, where it facilitates quality assurance processes or makes a substantial contribution to research and development.

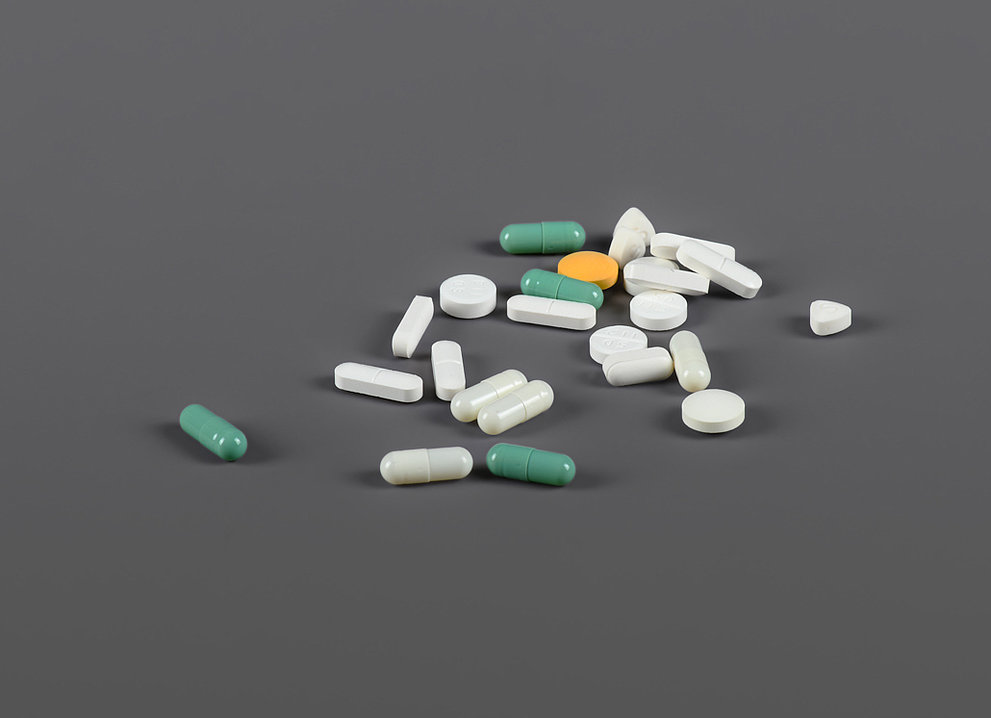

Pharmaceutical Application

In the pharmaceutical industry, materials come into contact with water in many ways, such as during processing steps like crystallization, spray drying, and wet granulation. Additionally, pharmaceutical raw materials or finished products are usually exposed to a humid atmosphere during storage and transport, which leads to interactions between solid components and water. In multi-component formulations, water can migrate between moist and dry components. Regarding the compaction behavior during tableting, a certain moisture content is required to produce satisfying products.

Food Research

Water is one of the most critical components of food products, as moisture content and, specifically, water activity influence shelf life, quality, as well as physical and sensory properties. Examples include flowability, stickiness, crispness, or the texture of products, all of which change depending on the product moisture. A change, whether through an increase or loss of moisture, can occur during the transport, storage, processing, or handling of the product. In this process, moisture transfer can occur between individual ingredients or between the product and the environment. To further characterize these effects, the method of dynamic water vapor sorption is widely used in numerous applications in food research.

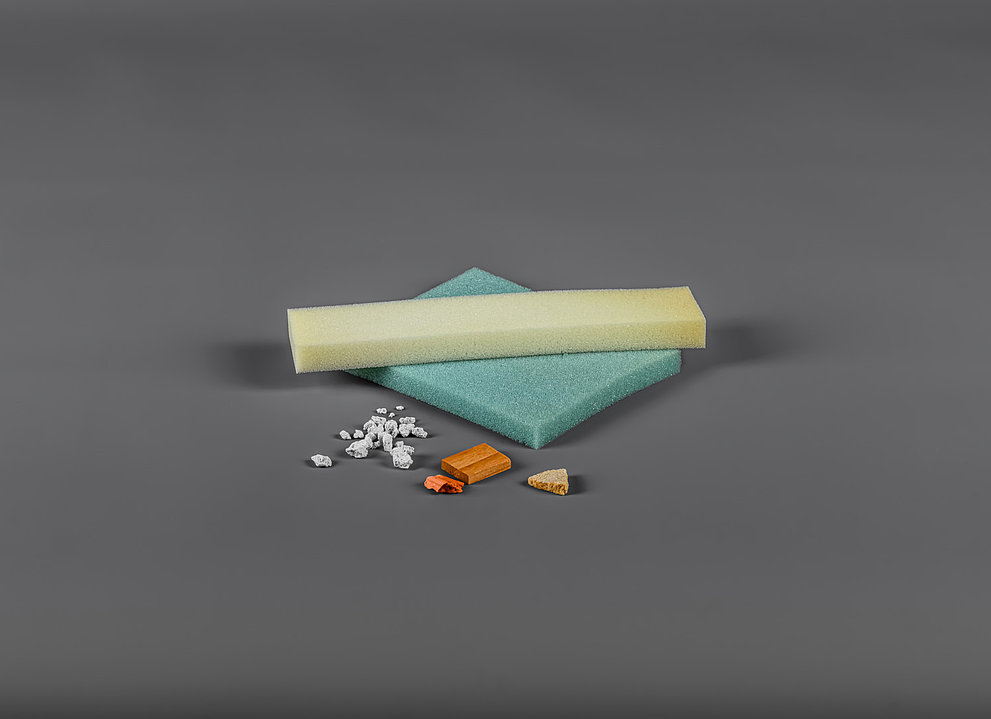

Building Materials

The term "building materials" encompasses a large group of various materials such as concrete, gypsum, ceramics, wood, materials for moisture and thermal insulation, as well as paints and varnishes. These heterogeneous materials are used in many different areas. Examples include the construction of buildings, interior finishing, or the renovation of buildings. In this context, the interaction of these materials with water plays an important role in assessing their suitability for a specific application.

Packaging & Permeability

Packaging materials and polymer films are intended to form a barrier against adverse climatic conditions to prevent the loss or uptake of moisture by the packaged product. The decisive criterion for this is water vapor permeability. Furthermore, the moisture uptake by the packaging material itself plays an important role in ensuring its functionality. For this reason, knowledge of water vapor sorption and permeability is absolutely essential to adapt a packaging material to the respective requirements.

DVS Basics

Dynamic water vapor sorption analysis is a precise and reliable method for investigating the temperature-dependent interactions between a material and the ambient humidity. The functionality of proUmid's sorption testing systems involves determining the weight change of a sample depending on the prevailing ambient conditions. In this way, information is obtained about the kinetics of water vapor sorption and desorption, as well as about the equilibrium state depending on a given relative ambient humidity.

DVS Add-ons

Additional sensors, such as a camera or Raman probe in combination with dynamic water vapor sorption analysis, enable deeper insights into moisture-induced material changes. The additional components can be easily attached to the proUmid instruments with specially developed sensor mounts. The full integration of the sensors into the SPS software allows for convenient measurement and evaluation of results. With the help of the camera system, it is possible to directly observe color changes, the occurrence of deliquescence, and humidity-dependent expansion or shrinkage of a material. Typical applications of Raman spectroscopy include the investigation of moisture-induced crystallization, hydrate formation, and the analysis of polymorphic forms. The combination of DVS analyses with additional sensor components thus enables not only an accurate and reliable investigation of the material-moisture interaction but also a more detailed understanding of the resulting changes in the material.

Powder Conditioner: Moisture Equilibration

Moisture equilibration is an important issue when material properties are affected by moisture. In order to study the influence of moisture on physical properties such as flowability or compressibility of dried materials, it is necessary to adjust the moisture content of the material. This is where the Powder Conditioner comes in, providing reliable moisture adjustment in preparation for further analysis such as powder rheology, flow or caking testers, or to study the processability of materials in terms of tableting, roller compaction or flow and dosing behavior. The Powder Conditioner can be used for almost all particulate materials such as powders, granules or pellets. The Powder Conditioner is based on the principle of the Dynamic Flow Method, where a moisture-conditioned gas stream is passed through the powder bed and the sorption/desorption behavior of the material is determined by balancing the inlet and outlet moisture. Another advantage of the Powder Conditioner is the software, which allows easy programming of conditioning and in-line monitoring with a graphical display of the conditioning process.