Permeability of Packaging Materials and Polymer Films

Packaging materials must provide a barrier function against unfavorable climatic conditions in order to prevent the loss or absorption of moisture by the packaged product. The key criterion here is the water vapor permeability of the material. Furthermore, the moisture absorption of the packaging material itself is essential for its functionality. It is therefore very important to determine the water vapor sorption and permeability in order to adapt a packaging material to the respective requirements. With the help of dynamic water vapor sorption analyses and the specially developed accessories, such as the Permeability Kit, the Inverted-Wet-Cup Kit and the Large Object Kit, these properties can be easily determined.

Application Notes

Water Vapor Permeability of Foils

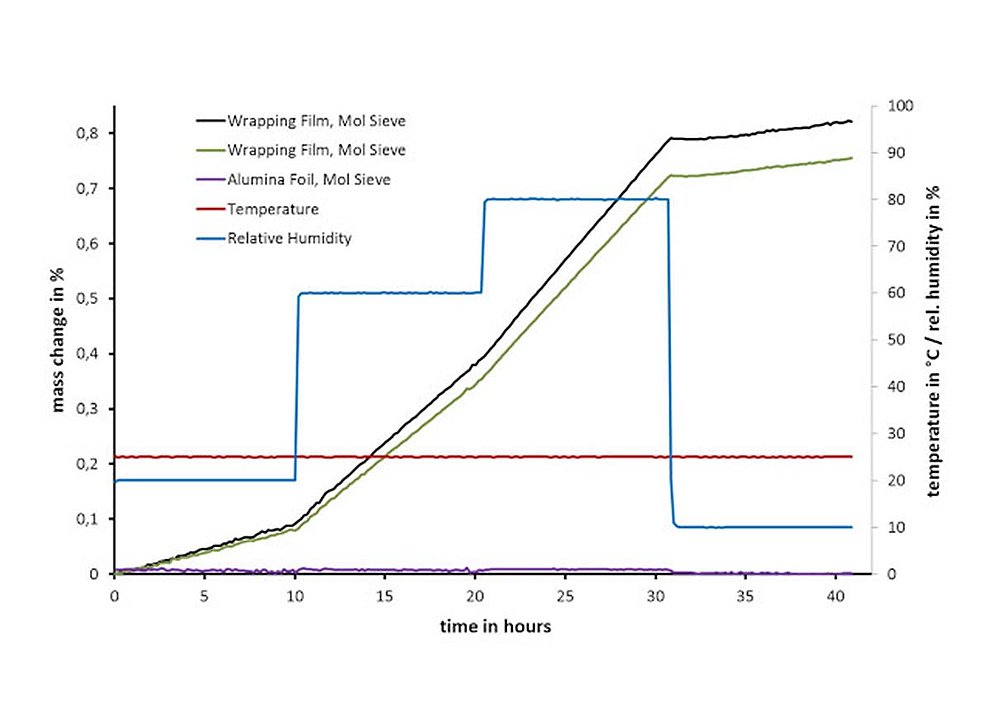

Application Note 12-01 presents a method for determining water vapor transmission rate using the proUmid DVS instruments. The principle of the method, the experimental setup, and the evaluation of the results are presented using packaging films and aluminum foil as examples. Furthermore, the influence of the ambient humidity on the water vapor transmission rate is investigated.

Water Vapor Sorption of Product Packages

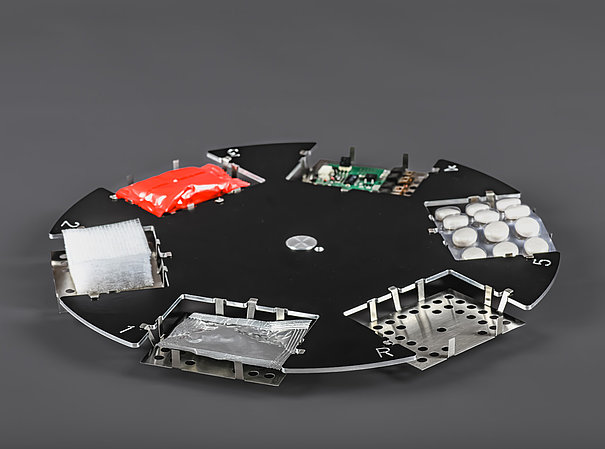

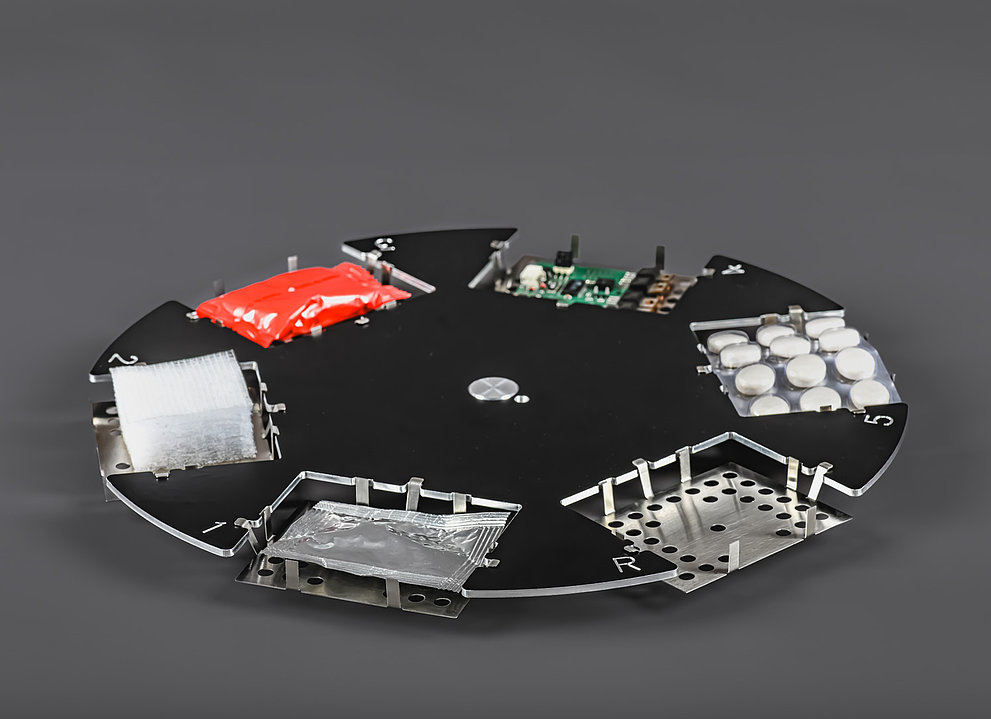

The flexibility of the proUmid sorption test systems allows not only standard DVS measurements, but also the measurement of complete product packaging using the Large Object Kit. This offers the possibility to test the barrier effect on the real packaging and thus to evaluate the influence of production-related defects such as closures or sealing seams on the water vapor permeability. Application Note 15-01 tests the sorption behavior and permeability of various packaging materials, including paperboard, plastic, and film-wrapped systems, and presents the results.

Inverted-Wet-Cup: Water Vapor Permeability of Materials in Direct Contact with a Liquid

Inverted-wet-cup analysis is the method of choice for measuring the water vapor permeability of a material in direct contact with a liquid, such as packaging materials for beverages or cleaning agents. Application Note 24-01 presents the experimental setup and sample preparation and explains the evaluation and calculation of the water vapor transmission rate using packaging materials in contact with various liquids as examples.

Shelf Life Calculation of Dry Food Products

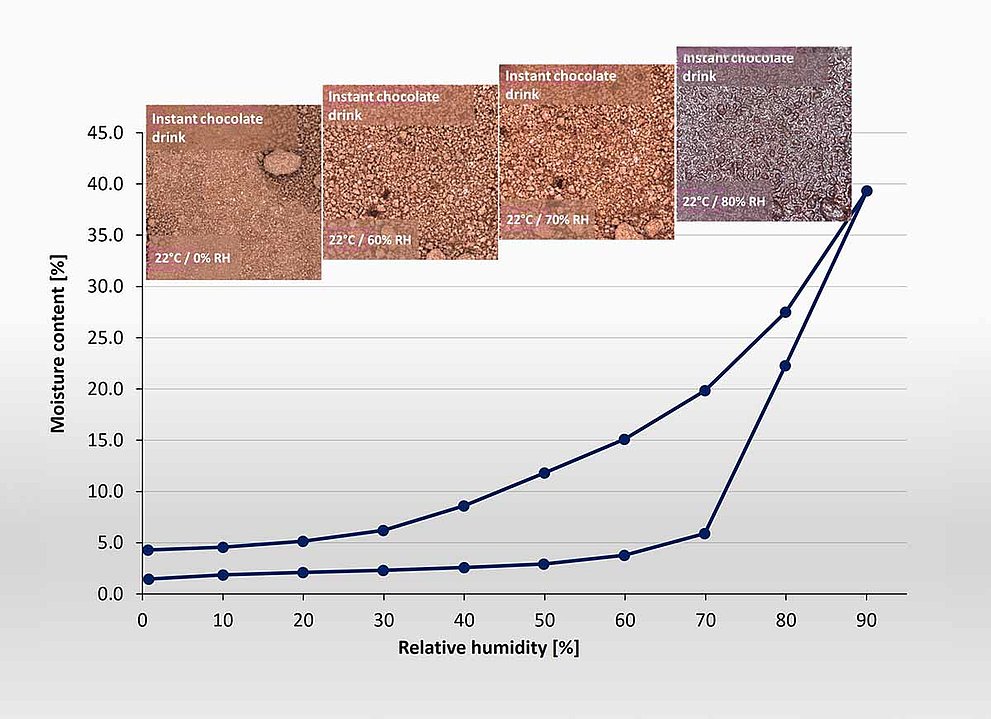

To ensure safety and quality, it is important to know the shelf life of a product. Storage conditions such as temperature and relative humidity play an important role, especially for dry products. To demonstrate the influence of these parameters on shelf life, several dry products were studied using dynamic water vapor sorption. The critical conditions leading to product changes were also verified using inline camera images. In addition to product properties, packaging also has a significant impact on shelf life. The relevant parameter is the water vapor transmission rate (WVTR) of the material. This value was determined using the Permeability Kit. Based on the product and packaging properties, White Paper 24-03 presents a method to calculate the possible storage time and thus to estimate the shelf life of a packaged product.

Literature References for determining Water Vapor Permeability using proUmid DVS Instruments

Sandra Kiese, et al. „Time-dependent water vapor permeation through multilayer barrier films: Empirical versus theoretical results“ Thin Solid Films 672, 199-205, 2019. DOI

Martina Lindner, et al. „Hygroexpansion, Surface Roughness and Porosity Affect the Electrical Resistance of EVOH-Aluminum- Coated Paper“ Coatings 9, 295, 2019. DOI

Markus Schmid, et al. „Impact of Hydrolyzed Whey Protein on the Molecular Interactions and Cross-Linking Density in Whey Protein Isolate-Based Films“ International Journal of Polymer Science, 2016. DOI