The Standard 5 kit is the compact solution for water-vapour permeability tests with up to five samples in parallel. Perfect for routine screening and quick material comparison when sample volume is limited.

Permeability kits are only compatible with SPS11-10μ, SPSx-1μ-High-Load and the entire Vsorp series.

The Standard 11 kit enables high-throughput testing of up to eleven samples in a single run. Ideal for R&D and QC labs handling large sample series.

Permeability kits are only compatible with SPS11-10μ, SPSx-1μ-High-Load and the entire Vsorp series.

The Inverted Wet Cup kit is designed for water-vapour permeability testing of materials in direct contact with liquids. It prevents sample wash-out and guarantees stable test conditions.

Permeability kits are only compatible with SPS11-10μ, SPSx-1μ-High-Load and the entire Vsorp series.

Select the desired model

Current selection:Permeability Kit Standard-5Permeability Kit Standard-11Permeability Kit Inverted Wet Cup

- Tests 5 samples simultaneously

- Fits all SPS and Vsorp instruments

- Quick sample change via bayonet lock

- Stainless-steel parts comply with FDA

- Tests 11 samples simultaneously

- Uniform gas flow across all positions

- Heavy-duty design for continuous use

- Works with automatic data logging

- Measures under liquid contact

- Reversible cup geometry eliminates leaks

- Simultaneous control of temperature and humidity

- Validated according to ISO 2528

-

Simultaneous Multi-Sample Analysis

Enables the simultaneous determination of permeability on up to 5 or 11 samples.

-

Compatibility with SPS and Vsorp Systems

Easy integration into existing proUmid sorption testing systems.

Water Vapor Permeability of Foils and Films

Determining the water vapor permeability of packaging materials such as paper, plastic films, or carrier foils is an important task. Water vapor permeability plays a critical role in the quality and shelf life of a product, especially in regions with extreme climatic conditions. In industries that work with moisture barriers, films, and membranes, a reliable method for measuring water vapor transmission is essential.

In many cases, both sorption analysis and water vapor permeability testing are required. The sorption analysis systems of the SPS and Vsorp series are ideally suited for this purpose. They feature a high-precision microbalance and a large measuring chamber with controlled temperature and humidity, allowing both measurement methods to be combined in a single device.

Kits for SPS Systems and Vsorp Instruments

proUmid offers various kits for different measurement methods for the gravimetric determination of water vapor permeability of foils and films for both SPS systems and Vsorp instruments.

Standard Permeability Kits

The standard Permeability Kit enables the determination of the amount of water vapor transmitted through foils or films with a defined surface area under controlled humidity conditions over a specified period of time.

Simultaneous testing of up to 5 or 11 samples is possible. The loaded sample dishes are placed on a tray and inserted into the measurement chamber of the sorption system, where testing is performed under controlled temperature and humidity conditions. The method is based on EN ISO 7783-1 Part 1: “Dish method for free films.”

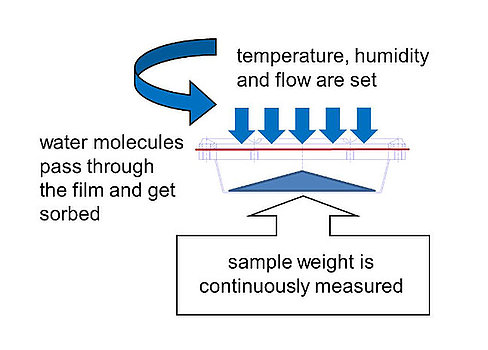

Measurement Procedure Standard Permeability Kits

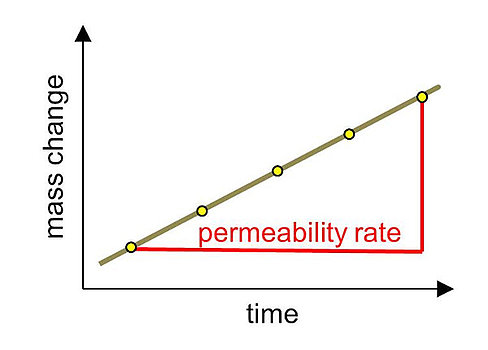

The sample dishes are filled with a desiccant, water or humidity standard. The sample itself is fixed by the clamping frame of the dish. A difference in the partial water vapor pressure between the controlled climatic conditions inside the measurement chamber and the sample dish inside is established causing a migration of water molecules through the film. The result is a constant change in mass of the sample dish that is recorded by the analytic balance of the instrument. The water vapor permeability rate is determined from the linear slope of this sorption curve.

Measurement Procedure Inverted-Wet-Cup Kit

Sample dishes, filled with water or another liquid, are placed upside down in a drip dish on the sample tray. This ensures that the sample material is in direct contact with the liquid. This method is used, for example, to test the permeability of liquid products (e.g., detergents) through packaging materials. At a constant temperature and defined relative humidity, the amount of water vapor diffusing through the sample material is determined by continuous weighing. A drip dish beneath the sample dish catches any liquid that may leak out and protects the device from contact with the liquid.

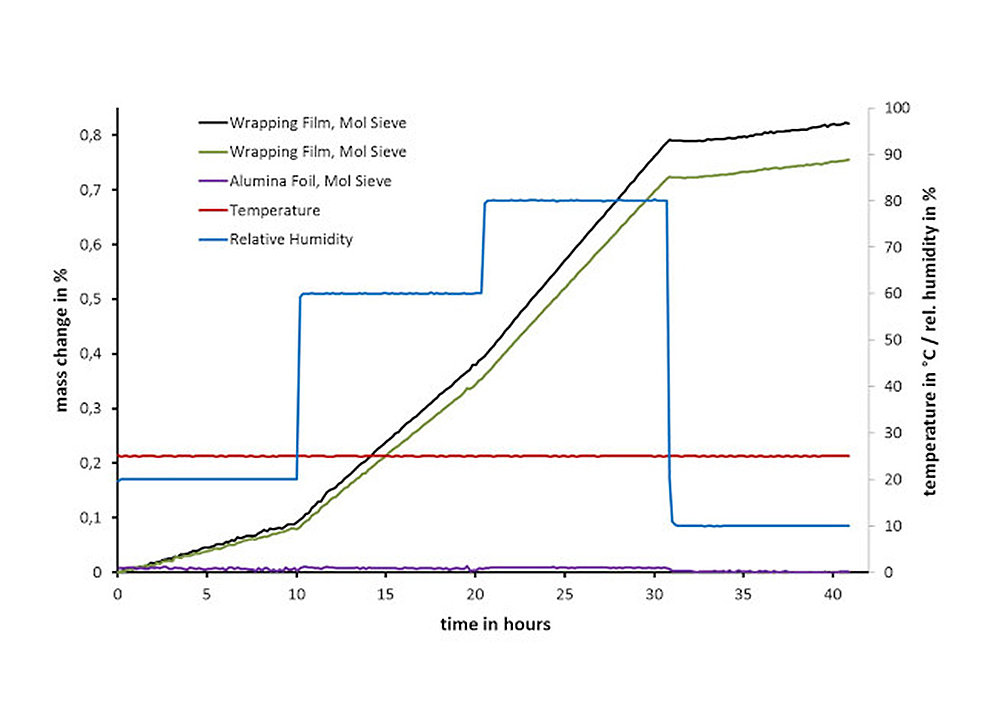

Water Vapor Permeability Example

The diagram shows results of a water vapor transmisson measurement performed with commercially available cling film. The permeability rate was determined at different RH levels. For further reading please download the corresponding Application Note 12-01 Water vapor migration through films.