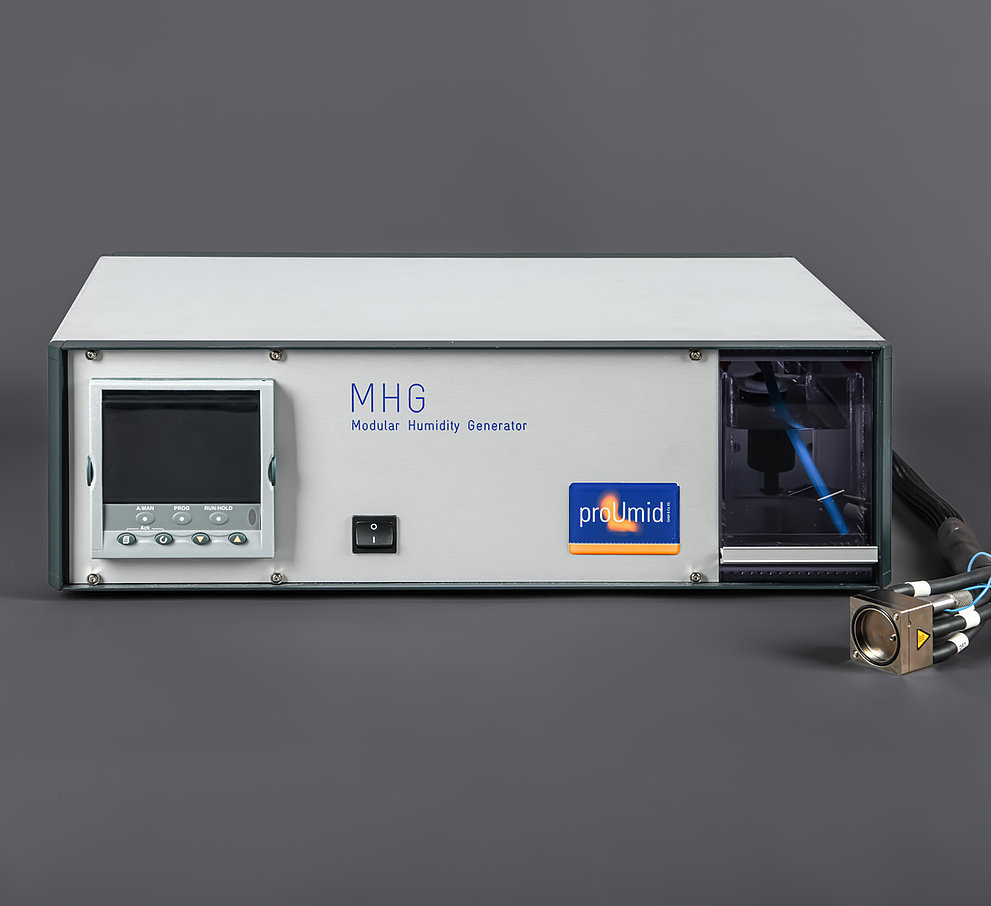

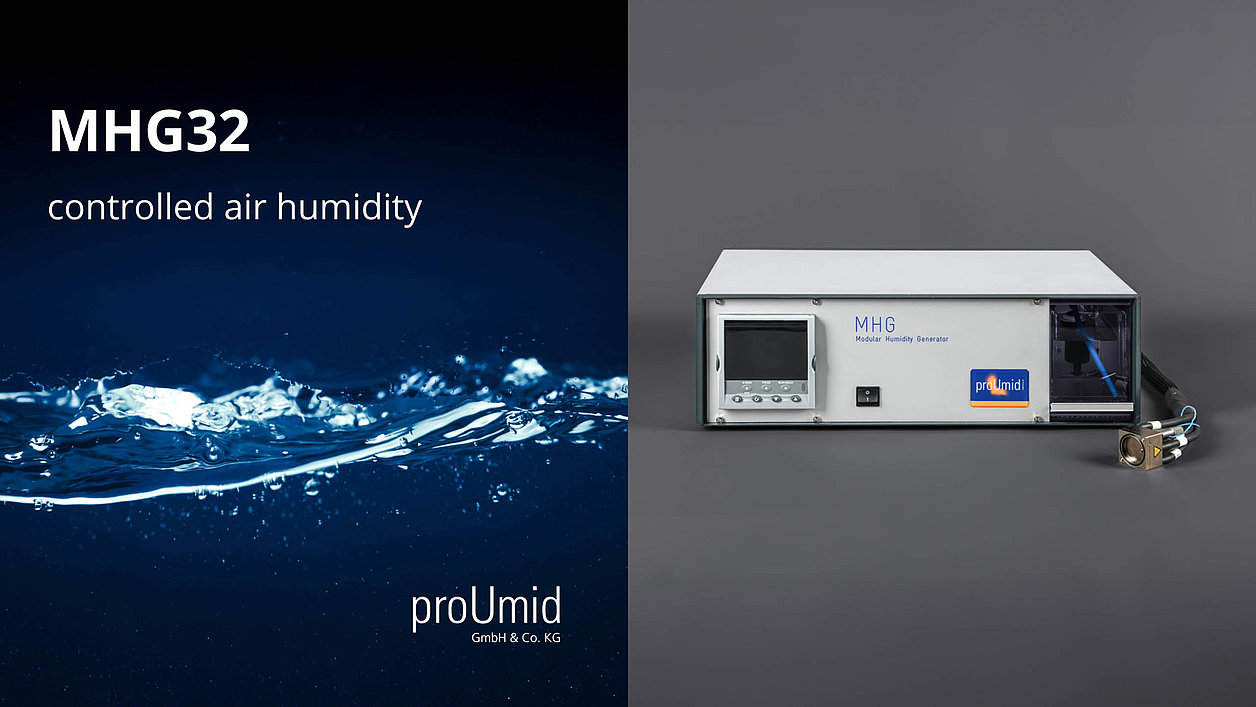

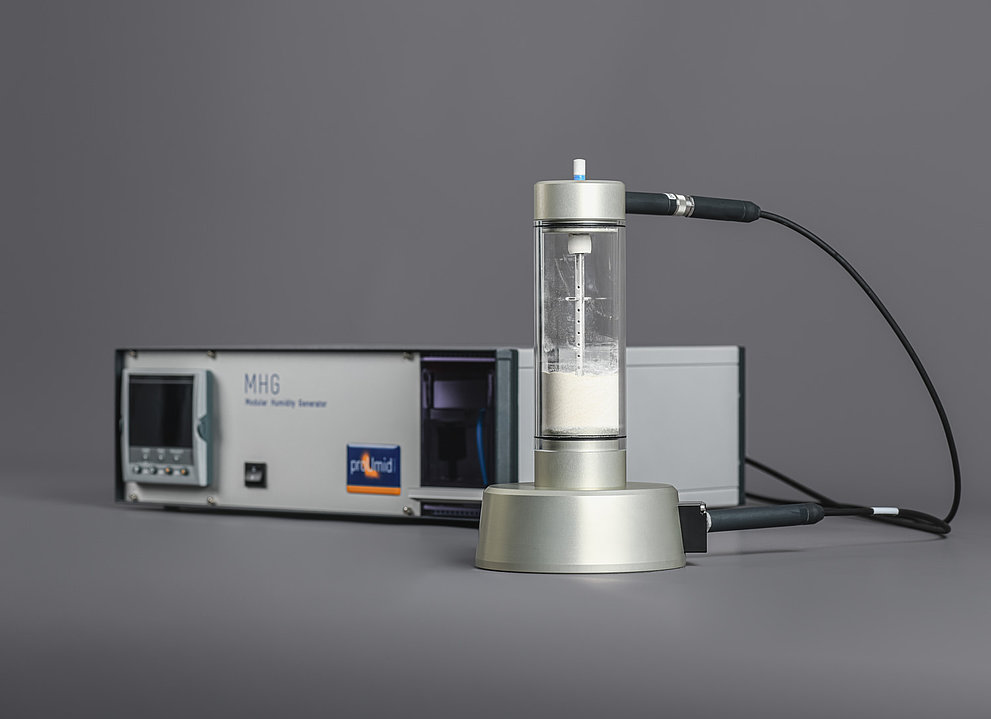

The MHG32 is a modular humidity generator specifically developed for applications in demanding instrument environments with small volumes, where rapid changes in relative humidity are required. By generating and controlling humidity directly at the measurement object, it enables fast and precise control behavior, even with very small flow rates.

The MHG32 is a modular humidity generator specifically developed for applications in demanding instrument environments with small volumes, where rapid changes in relative humidity are required. By generating and controlling humidity directly at the measurement object, it enables fast and precise control behavior, even with very small flow rates.

The MHG32 is a modular humidity generator specifically developed for applications in demanding instrument environments with small volumes, where rapid changes in relative humidity are required. By generating and controlling humidity directly at the measurement object, it enables fast and precise control behavior, even with very small flow rates.

Select the desired model

Current selection:MHG32 StandardMHG32-TCMHG32-100/TC

- Humidity regulation 0 – 98% RH

- Flow rate up to 1000 ml/min

- Modular system with external mixer

- External temperature control (e.g., climate chamber)

- Integrated temperature control up to 80 °C

- Flow rate up to 1000 ml/min

- Humidity directly at the target volume

- Closed temperature control loop with sensor

- Humidity regulation 0 – 98% RH

- For small flows: 0 – 100 ml/min

- High precision with low gas volume

- Compact design for small volumes

-

Fast and Accurate Humidity Regulation

Closed loop regulation with very short response times.

-

Fits a Wide Range of Applications and Test Environments

Dynamic flow rates and variable control parameters for perfect adaptability to your target system.

-

Wide Temperature and Humidity Range

Customized setup allows operation in extreme temperature conditions.

-

Maintenance Free Operation

No regular service needed.

Key Features of the MHG32:

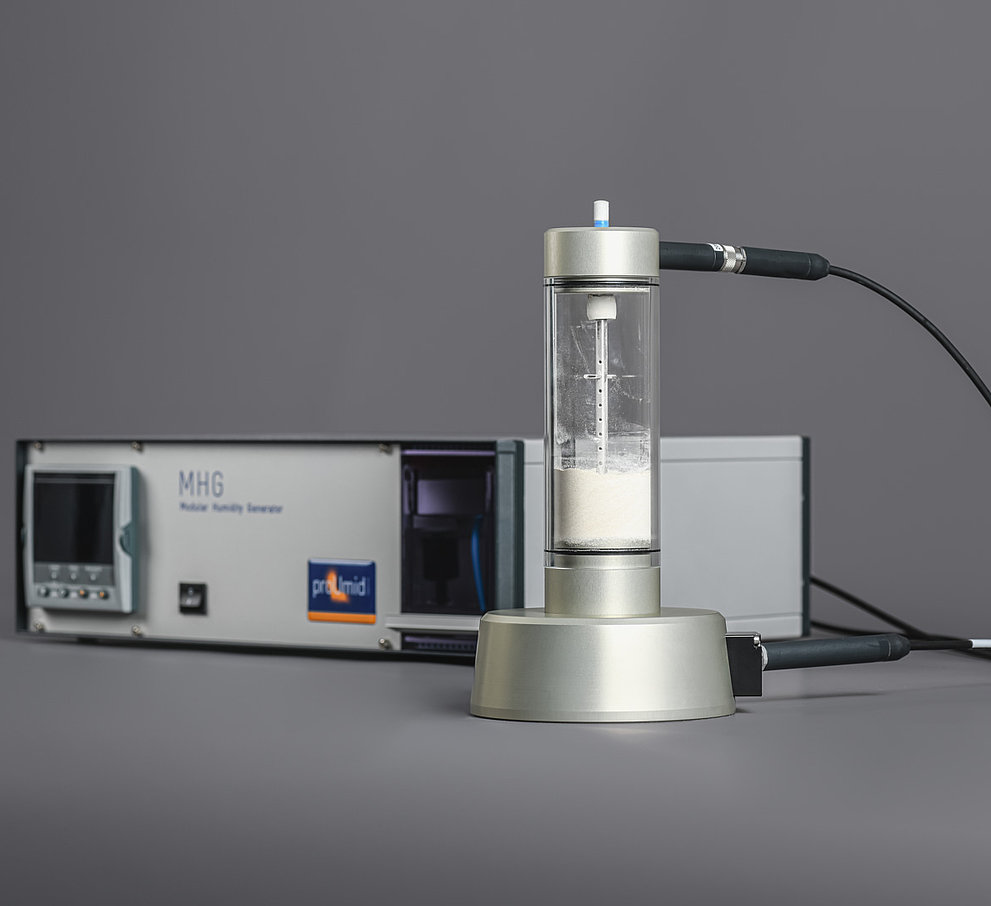

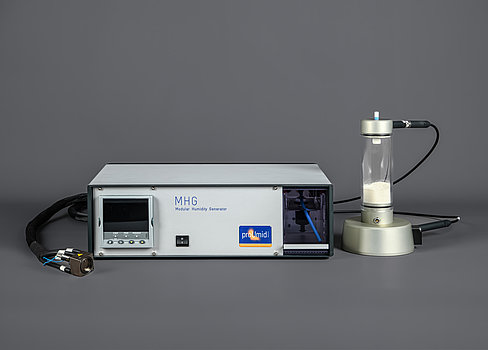

The MHG32 system is designed for controlled humidity in challenging instrument environments where quick changes of relative humidity in small volumes are required. The unique feature of the MHG32 is the generation and control of relative humidity directly at the target volume and thus enabling a fast and accurate response even at very low flow rates.

The MHG32 is available with maximum flow rates of 100 ml/min, 500 ml/min or 1000 ml/min and is suitable for chamber volumes from approx. 20 ml up to 2000 ml. The modular setup and easy adaption in combination with the wide temperature and humidity range makes the MHG32 a perfect match for all kind of applications. The large number of possibilities for customization allows for an easy integration of the MHG32 as an OEM product into analysis instrument solutions.

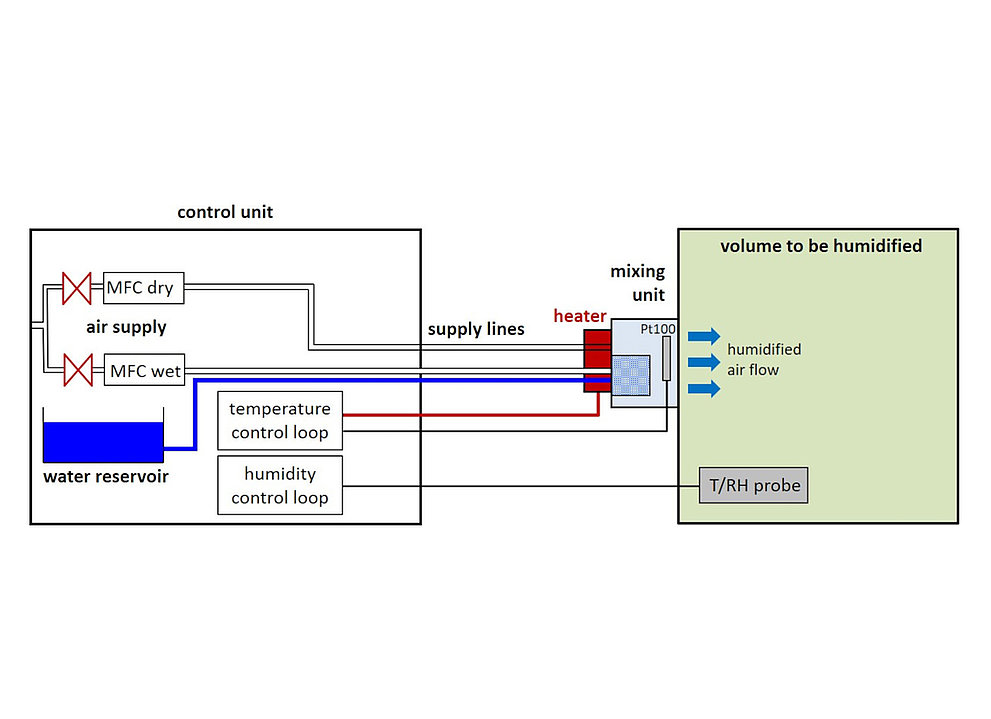

Unique System Architecture

The patented design of the MHG32 is different from a standard instrument for controlled humidity. Usually, a flow of humid air is generated inside the instrument and then transported via a heated transfer line to the target system or volume to be humidified. Such a configuration results in large dead volumes in the supply lines and a slow control behavior.

The unique, patented design of the MHG32 enables exceptionally fast and precise control performance. The gas flow with defined humidity is generated directly in the mixer, connected to the outer wall of the target volume.

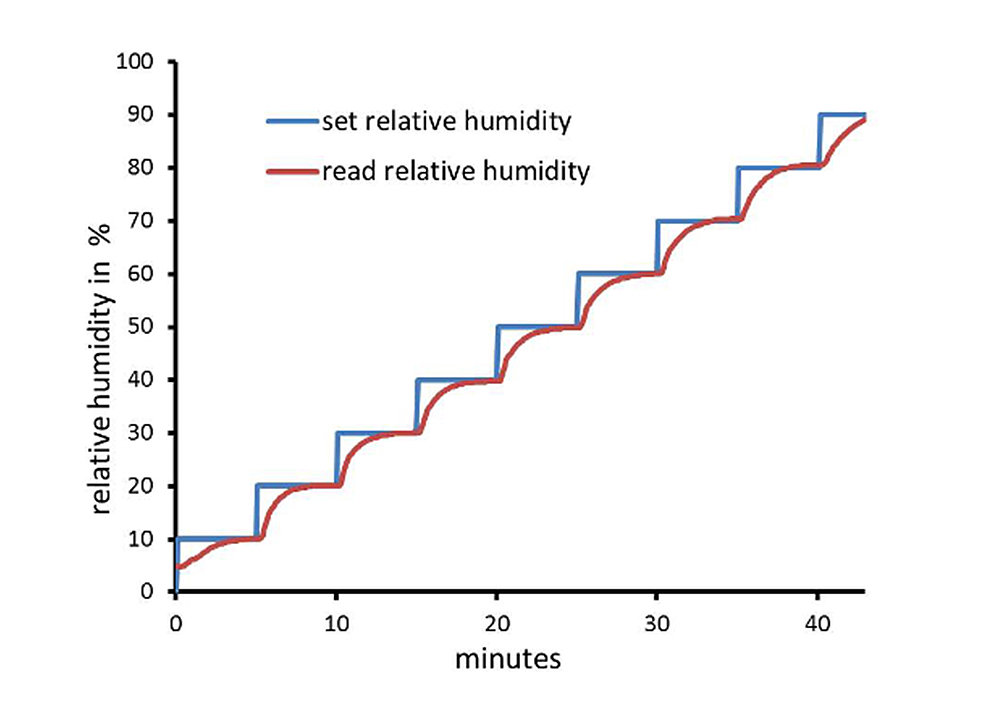

Precise Control

- Fast and Precise Control of Humidity

Generating the gas flow directly at the volume to be humidified eliminates any dead volume in the supply line. As a result, fast and precise humidity control is consistently ensured, even at very low flow rates.

- Closed Control Loop

The humidity and temperature sensor of the MHG32 is placed directly within the volume to be humidified, making the target system an integral part of the control loop. This sensor placement enables the MHG32's fast, stable, and robust control performance.

Temperature and Humidity Range

The mixing unit is small but powerful and allows for precisely controlled humidity over the full temperature and humidity range.

- Intergrated Temperature Control: MHG32-TC

The MHG32 with the option TC provides active temperature control with a heating system directly inside the mixing unit connected to the system to be humidified.

- For Precise Humidity Regulation at Low Flow Rates: MHG32-100

The MHG32-100 is equipped with high precision flow controllers for humidity regulation at very low flow rates up to 100ml/min.

- External or Passive Heating/Cooling

The MHG32 is also available without active temperature control for applications around room temperature or in which a customer-specific heating/cooling system is used. The mixing unit can be externally heated or cooled in the range from 2 °C to 95 °C.

For applications without active temperature control, a heater inside the mixing unit compensates for the unavoidable evaporation enthalpy during humidification. This ensures precise humidity control up to saturation across the full temperature range. Even when the mixer head is only passively heated by thermal conduction.

High Degree of Customization

The MHG32 can be operated locally via the front panel or by remote control via RS232 or Ethernet. The Modbus software interface is fully configurable and allows for complete integration into the control software of the target system.

- Humidity Sensor

The sensor interface is fully configurable. Any sensor with an analogue signal output can be connected.

- Operation & Software Interface

The MHG32 can be operated locally via the front panel or by remote control via RS232 or Ethernet. The software interface is fully configurable and allows for complete integration into the control software of the target system.

- Additional Options

- Miniaturized T/RH sensor for tiny volumes and narrow spaces

- Additional temperature sensor for thermally separated samples (e.g. on a heat or cooling stage)

- Sensor antechamber for systems that do not allow to place the humidity sensor inside the target volume

* The minimum achievable humidity depends on the water content of the carrier gas. Deviation data based on Rotronic HC2A-S sensor.

** External heating / cooling can be adapted by the customer. Temperature range: Min. 2 °C to Max. 95 °C.

*** Other gases on request. By default, flow controllers are calibrated to air as the carrier gas.