Water Vapor Permeability of Foils and Films

Determination of the water vapor permeability is of major importance for many materials such as paper, plastic films and foils and other sheet materials product packages are made of. Knowledge and control of the water vapor transmission rate (WVTR) into and out of a packaging is a key factor in maintaining the quality of a product even in regions having widely varying environmental conditions. Packaging engineers and also product developers from all industries where moisture migration through a thin barrier layer, foil or membrane is of importance, require a measurement method to generate precise, reliable and repeatable test data.

Very often sorption analysis and water vapor permeability are both needed for the same application. Providing a highly sensitive analytical balance and an environment of controlled temperature and humidity, the SPS and Vsorp sorption systems are perfectly suited to combine both measurement methods in a single instrument.

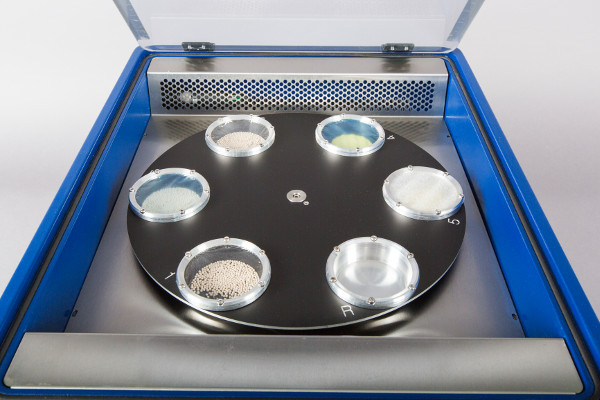

ProUmid offers different permeability kits for different permeability applications that can be used with the SPS systems as well as with the Vsorp instruments.

Standard permeability kits

The permeability kit enables the determination of the amount of water vapour transmitted through a foil/film with a given surface area and under controlled humidity conditions during a specified period of time. The permeability kit works as described in EN ISO 7783-1 part 1: “Dish method for free films”.

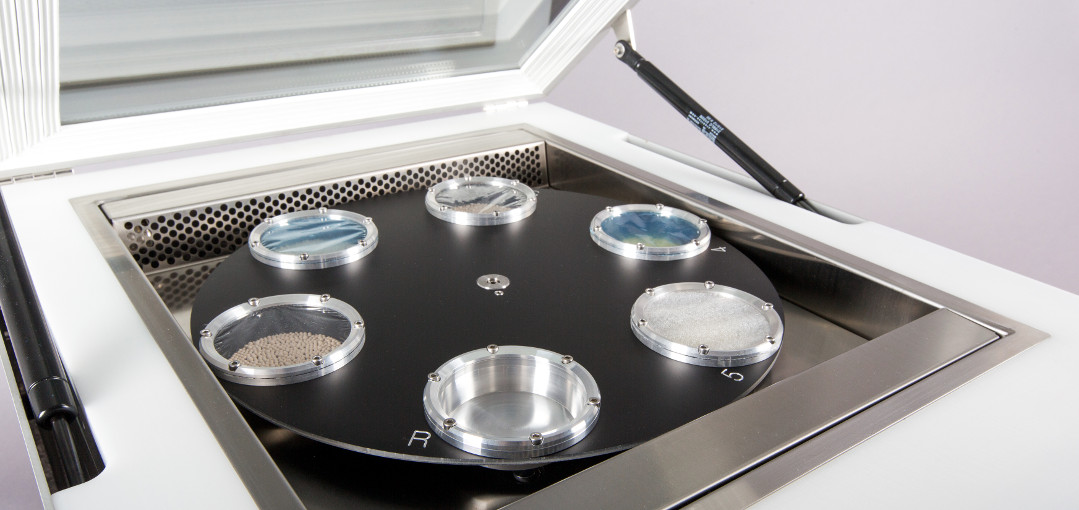

Simultaneous testing of 5 or 11 samples is possible. The sample tray with the sample dishes is placed inside the test chamber of the instrument for measurement under controlled conditions (temperature, humidity and flow).

Measurement procedure

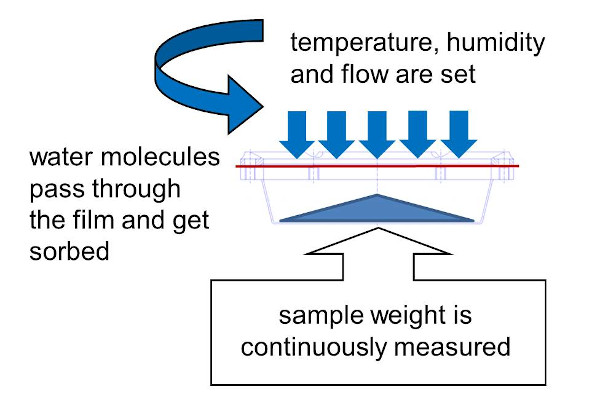

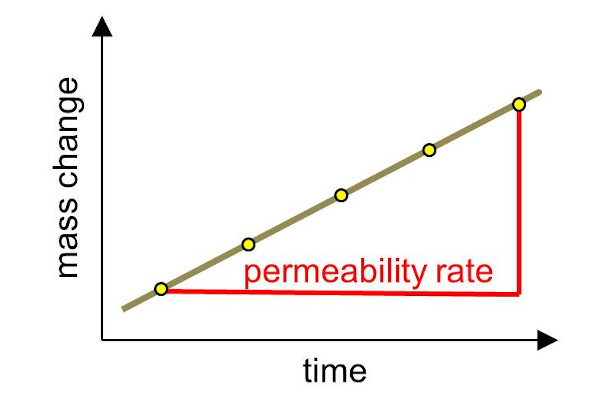

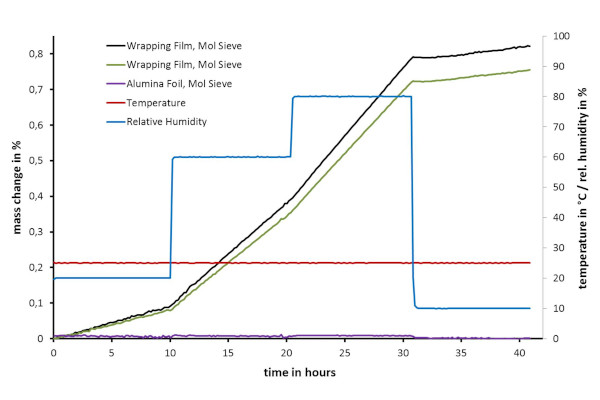

The sample dishes are filled with a dessicant, water or humidity standard. The sample itself is fixed by the clamping frame of the dish. A difference in the partial water vapor pressure between the controlled climatic conditions inside the measurement chamber and the sample dish inside is established causing a migration of water molecules through the film. The result is a constant change in mass of the sample dish that is recorded by the analytic balance of the instrument. The water vapor permeability rate is determined from the linear slope of this sorption curve.

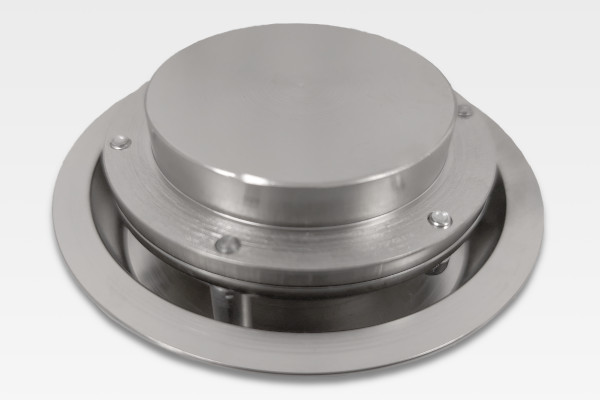

Inverted-Wet-Cup Kit

The sample pans filled with water or other liquid are placed upside down in drip pans on the sample tray. The sample is in direct contact with the liquid. This method is used for example, to test the permeability of a liquid product (e.g. liquid detergent) through the packaging material it is in direct contact with. The amount of vapor from the inside liquid that diffuses through the sample film, at a constant temperature and defined relative humidity in the measuring chamber of the device, is determined by continuous weighing. A drip pan below the sample pan catches any liquid that may potentially leak from the sample pan, protecting the instrument from getting in contact with the sample.Water vapor permeability example

Contact us for more information on the permeability kit

Technical Specifications

| type | Standard 5 | Standard 11 | Inverted Wet Cup Method |

| number of samples | 5 samples & 1 reference | 11 samples & 1 reference | 5 samples & 1 reference |

| sample area | 3500 mm² | 2273 mm² | 1507 mm² |

| minimum detectable transmission rate | 0.05 g/(m²*day) | 0.05 g/(m²*day) | 0.01 g/(m²*day) |

| accuracy | within the minimum detectable transmission rate | within the minimum detectable transmission rate | within the minimum detectable transmission rate |

| max film thickness | up to 1 mm (depending on material properties) | up to 1 mm (depending on material properties) | up to 1 mm (depending on material properties) |

| sample cup dimensions | outer diameter 80 mm inner diameter 66.8 mm height of sample dish 22 mm | outer diameter 67 mm inner diameter 53.8 mm height of sample dish 23 mm | outer diameter 60 mm inner diameter 43.8 mm height of sample dish 10 mm |

| compatibility | the Permeability Kit can be used with the following sorption instruments: Vsorp Basic Vsorp Plus Vsorp Enhanced SPS11-10µ SPSx-1µ-High-Load | the Permeability Kit can be used with the following sorption instruments: Vsorp Basic Vsorp Plus Vsorp Enhanced SPS11-10µ SPSx-1µ-High-Load | the Permeability Kit can be used with the following sorption instruments: Vsorp Basic Vsorp Plus Vsorp Enhanced SPS11-10µ SPSx-1µ-High-Load |