The proUmid Powder Conditioner enables precise humidity conditioning of powders, granulates, and bulk samples. By controlling the relative humidity, material properties are optimized to improve processing steps such as tableting or dosing.

- Precise humidity control

- Versatile application

- Automatic process control

- Compact design

-

Accurate and Rapid Moisture Equilibration

Enables precise adjustment of relative humidity from 2 % to 95 % RH for optimal material conditioning.

-

Water Activity / Water Absorption Capacity

Suitable for powders, granules, pellets, and chunky samples up to a volume of 200 ml.

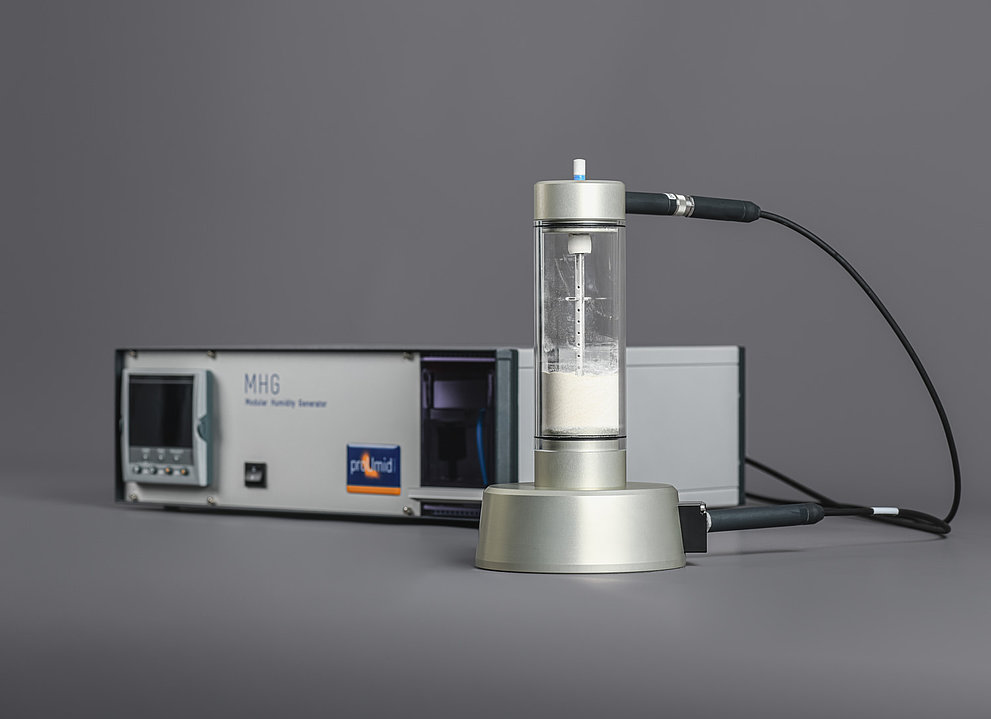

Moisture Equilibration – The Powder Conditioner

Moisture content can have a significant impact on powder properties such as flowability or compressibility. Measurement of mechanical properties at certain moisture contents therefore is essential in order to avoid problems during processing, storage and transport. The proUmid Powder Conditioner enables moisture equilibration of particulate systems such as powders, granules or pellets at controlled relative humidity.

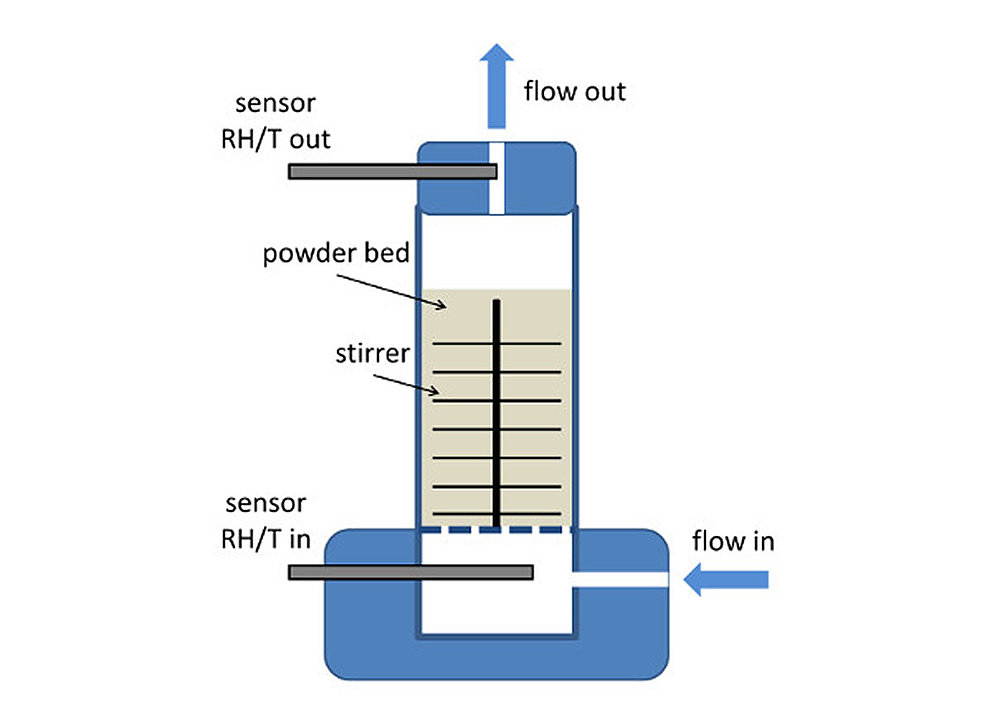

Dynamic Flow Method

A defined gas flow with controlled relative humidity is passed through a powder bed. Temperature and humidity at the gas inlet and outlet are recorded. The formation of lumps or air channels inside the powder bed is inhibited by continuous agitation. Completion of the humidity conditioning process is automatically determined by the instrument.

Humidity Control

The powder conditioner is connected to the proUmid MHG32 Humidity Generator or comparable equipment that provides a humidity controlled gas flow.

Applications for Moisture Equilibration

- Powder Analysis

Pre-treatment of powders for analysis of bulk properties with a certain moisture content using equipment such as powder rheometer, flow tester, caking tester or ring shear cell.

- Processibility

Processability of powders with a certain moisture content in processes such as tabletting, roller compaction, filling and dosing.

- Add-on: Water Content Determination

Water uptake of the powder can be calculated from the gas flow rate and the temperature and RH readings by a software algorithm. Successive execution of humidity steps enables to record the sorption isotherm of powdered material.

Technical Specifications

* in connection with the MHG32 humidity generator.

** when placed in a temperature controlled environment.